Development and prototyping

A full development service. From ideas through testing to a functional prototype.

Since 2016, we have been providing services to companies from marketing to industry sectors.

A full development service. From ideas through testing to a functional prototype.

Creating a functional copy of a broken part. We design modifications that will increase the lifespan of the part while reducing the replacement cost.

We will create parametric 3D models, drawing documentation, visualizations and print data based on your documents.

Dynamic production on our print farm. Fast iteration and adaptation to new requirements even during the production process.

We combine technologies and materials. Production, assembly, testing, packaging. We'll arrange anything we can't do ourselves.

Physical presentation materials - logos, key rings, gifts. Miniatures of your products. The possibilities are unlimited.

Speed of delivery and quality!

Excellent cooperation from the agreement to the final product.

Satisfied in all aspects and looking forward to further cooperation.

Great communication, speed of delivery and price

Great help in solving complicated tasks - knowledge about special materials and the range of technologies.

The requirement of the Czech company ReMobil was to develop a visually attractive, safe, practical and environmentally friendly collection container. In addition, it comes in two sizes.

Our large container is now provided to customers with the highest demands. This is not only due to its functionality and appearance, but also to the possibility of customising the individual components according to the customer's needs.

Our containers are used by T-Mobile, the Smíchov shopping centre, the Prague 13 district and others...

We used a combination of a metal frame, custom plastic parts and plexiglass. The container is modular, practical and safe also thanks to the rotary throw mechanism. In addition, most of the container can be made from recycled materials.

A customer contacted us with the problem that the rollers with a specific geometry were breaking through in the door opening mechanism and could no longer be obtained as a spare part.

Our solution was to manufacture new rollers that cost a fraction of the price of a new mechanism.

We used nylon as the material for the rollers - a difficult-to-print plastic, but its abrasion resistance made it a necessary choice for a long-lasting solution. In addition, using print in place method makes the roller a single robust part without the need for subsequent assembly, reducing costs for both ourselves and the customer.

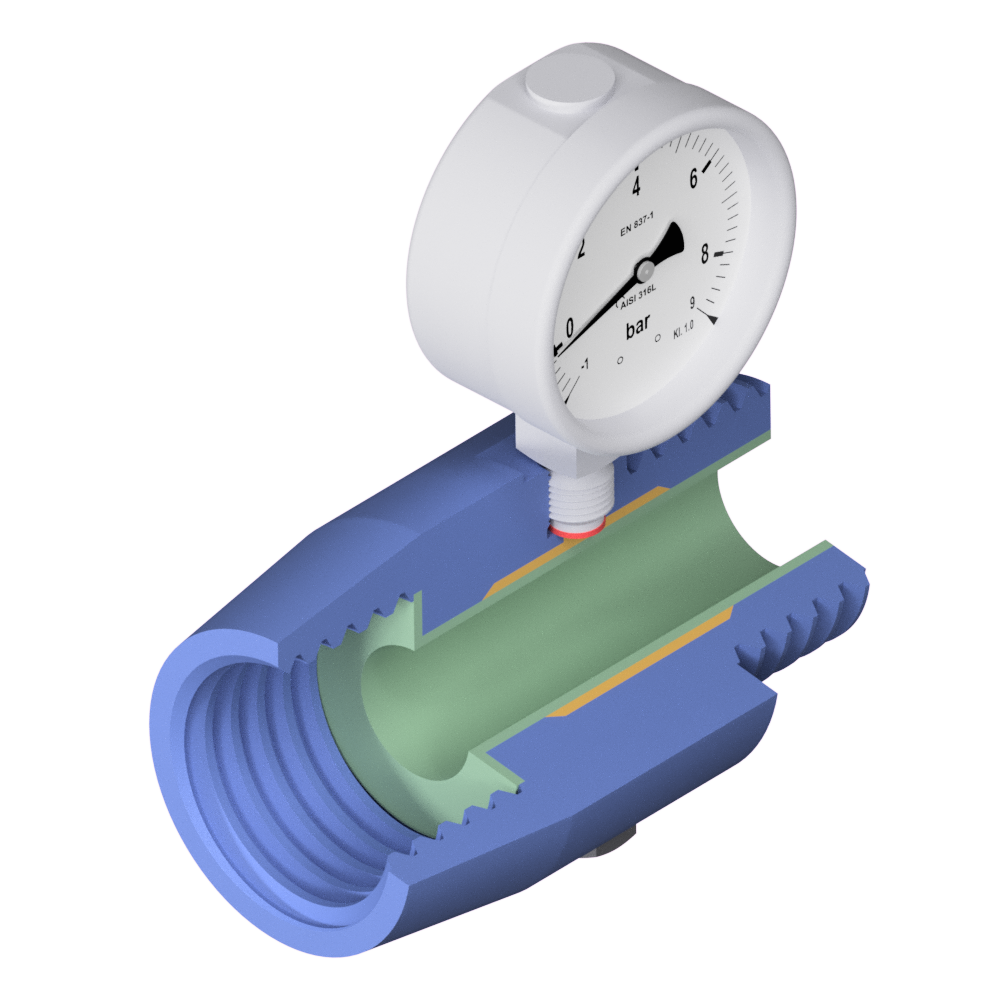

The Czech company BHV Senzory approached us with a request to create 3D data for the products they manufacture and sell. As an added bonus, we also proposed the creation of virtual cross-sections and assembly visualizations.

As a result, the products are now digitized and designers can insert them into their assemblies, which supports the sales of these products. In addition, we have created a set of visualizations for presentation, product sheets and easy explanation of the function of the products, for example at trade fairs.

We have licensed Fusion 360 to create models based on drawings, drafts as well as physical parts.

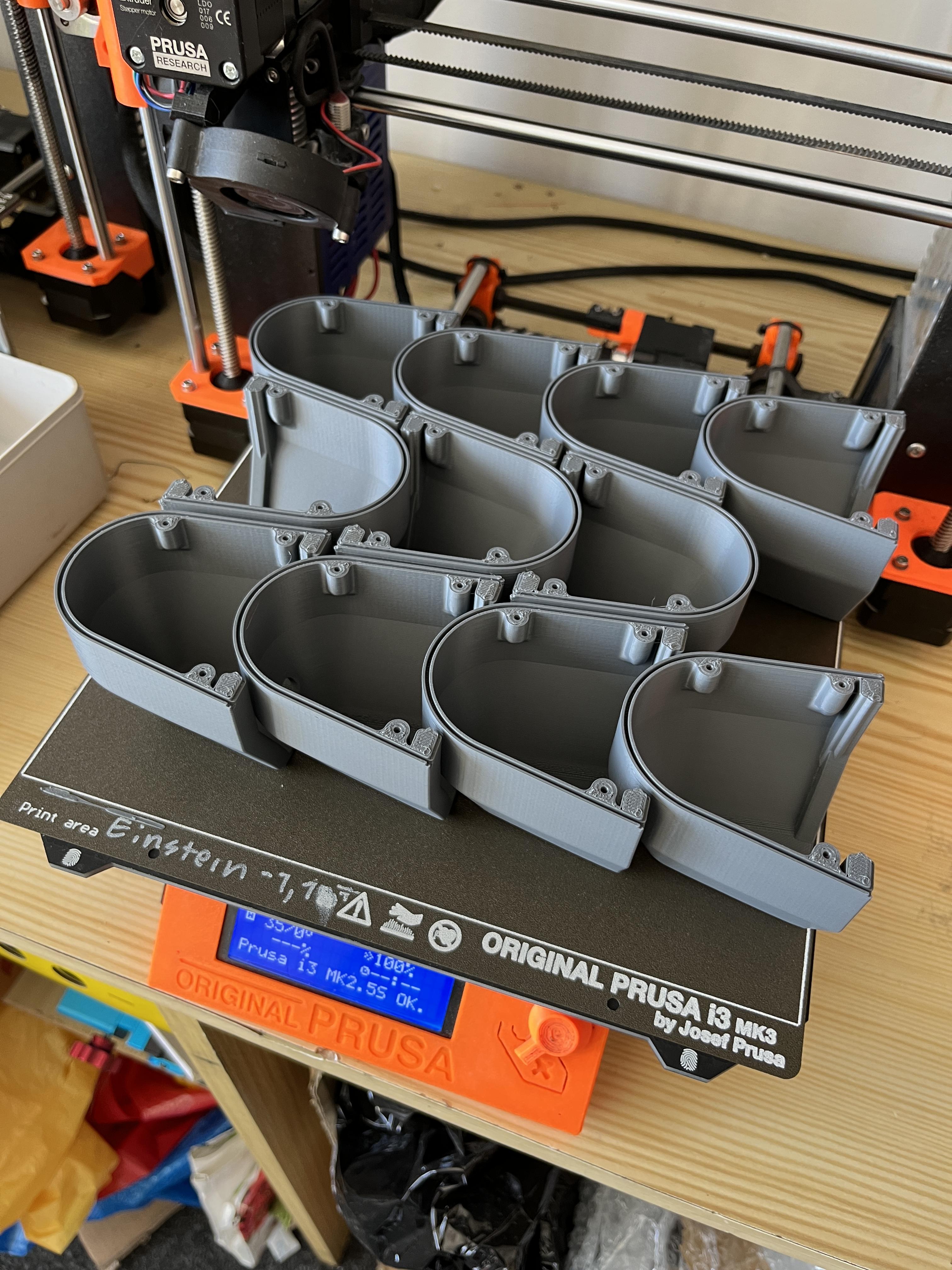

Czech company Inovec Technology is developing its own digital warehouse system. Cameras for use in industrial environments are an essential part of the technology.

We helped the customer to manage a period when their internal capacities were not sufficient. We created our own print data to maximize the capacity of printing. In addition, we also offered the customer the possibility of printing from a more temperature-resistant material thanks to printers with heated print chambers.

With our flexible production, parts can be adjusted and dimensions can be fine-tuned while in production. Using the output from product testing, the production process itself can be adjusted on the go.

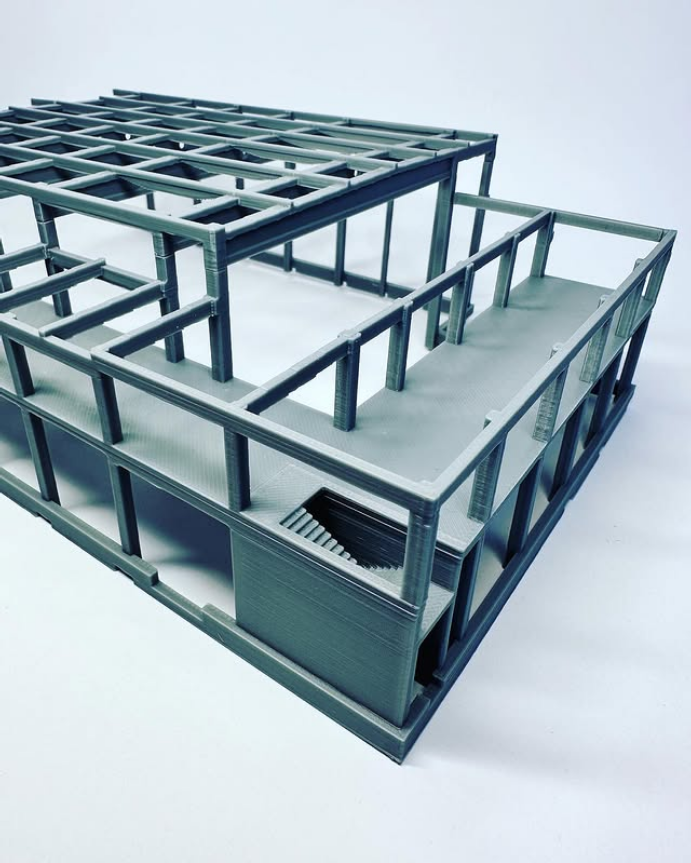

Czech company Prefa, which focuses on the production of concrete panels and constructions, contacted us with a request to produce a scale model of their recent realization as a gift for the customer.

Based on the provided ground plan and drawing documentation, we created a model with a total size of 500 mm.

The challenge in this project was to optimize the shape of the parts for an ease of printing, while maintaining the original look. The model consisted of about 100 parts, which we carefully glued together one by one.

With our flexible technology, we can produce a prototype within the next day, adjust the production process on the go and adapt to specific needs.

We invite you to come directly to us where we can work through your needs together, propose solutions and provide expert consultation.

Our technology allows production with a high level of detail. We pay attention to reliability and ergonomy right from the planning stage.

Call or e-mail for information about the company, billing, business.

📍 Rovná 224, Herink

📞 +420 722 819 013

✉️ martin@horakovic.cz

Call or e-mail for technical questions, requests, consultations.

📍 Benkova 1698/9, Praha

📞 +420 734 599 690

✉️ jakub@horakovic.cz